Marine

3D Concrete designs and manufactures custom 3D-printed concrete marine structures engineered to address the challenges of coastal erosion and ecological restoration of marine ecosystems.

Our modules are developed in collaboration with key partners in the field, including:

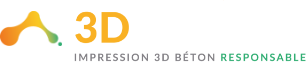

– LineUp Ocean, which has developed wave-attenuation modules that reduce wave energy while promoting sand anchoring, as well as reef systems designed to create habitats for marine fauna and flora;

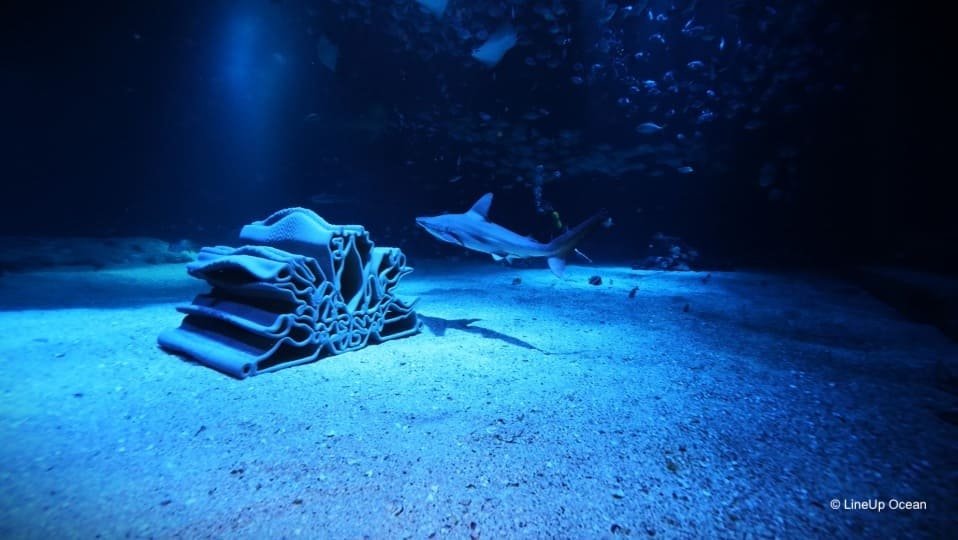

– Underwater Gardens, creators of bio-inspired artificial reefs that encourage marine repopulation;

– Fishwind, an ambitious initiative bringing together marine stakeholders, renewable-energy experts, and innovators to foster a harmonious coexistence between fishing, biodiversity, and offshore wind energy.

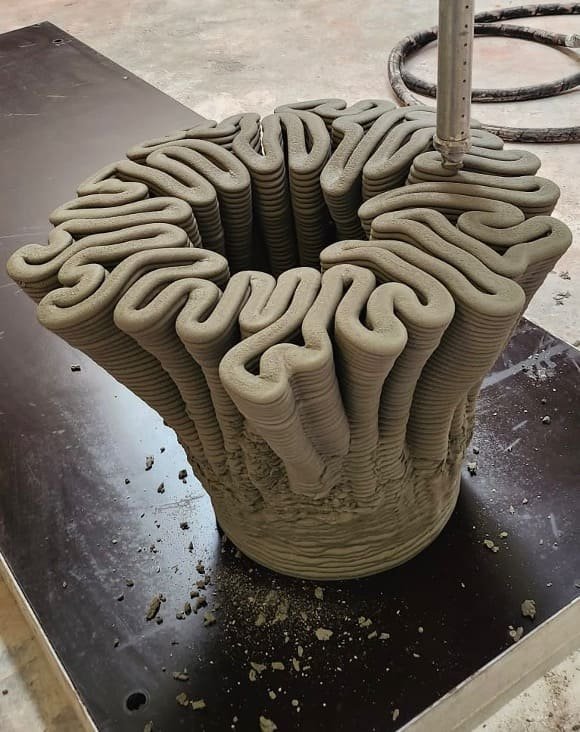

Each module is printed without formwork, through optimized concrete extrusion, using low-carbon materialsspecifically formulated for marine environments.

3D concrete printing offers complete design freedom, allowing the creation of cavities, porosities, and micro-habitatsthat enhance biodiversity, or complex hydrodynamic forms optimized for wave attenuation.

We manage the entire process — from prototype to series production, delivering custom modules ranging from under 100 kg to over 3 tons, while integrating transport, handling, and installation constraints.

Applications

– Coastal protection systems (wave-attenuation modules)

– Ecological artificial reefs

– Submarine installations for scientific, ecological, or tourism purposes

Benefits

– Formwork-free fabrication, fast and repeatable

– Low-carbon marine materials

– Parametric modeling for optimized geometries

– Local adaptation to specific biodiversity and environmental conditions

– Durable, modular, and easily transportable solutions

Specifications

100 % custom-made product, delivered ready to install

Unit weight: from 10 kg to over 3 t, depending on model

Custom finishes and concrete formulations available on request