Marine modules born from the meeting of 3D concrete printing and the ocean

Alongside LineUp Ocean, 3D Concrete applies its expertise in 3D concrete printing to the protection of marine environments.

Thanks to additive manufacturing technology that allows highly precise concrete extrusion, we produce submerged modules designed to host marine life while reducing the environmental footprint of coastal infrastructure.

Each piece is custom-designed and manufactured, following a low-carbon innovation approach adapted to living ecosystems.

Ecological ballast blocks for deep-water deployment

A first family of elements takes the form of ecological ballast blocks, visible in workshop images.

Their geometry, achieved through layer-by-layer concrete extrusion, is optimized to provide mass, stability, compactness and support for underwater life development.

These blocks serve as foundations for various technical systems deployed in deep-water zones.

The use of additive manufacturing in 3D concrete printing eliminates traditional formwork, reduces material consumption and enables fast production of robust and durable module series.

3D-printed artificial reefs designed to host marine life

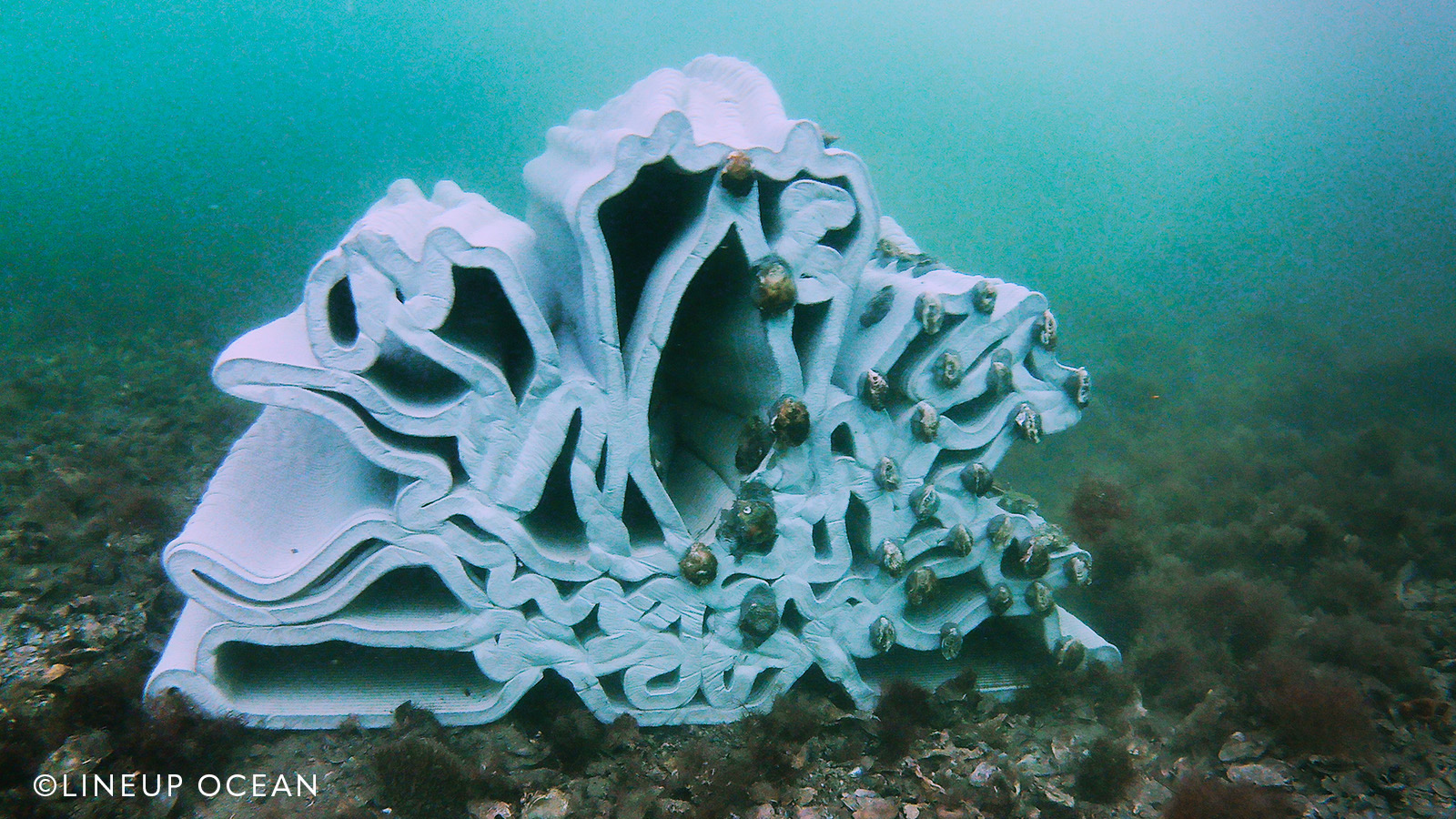

The second major typology of modules developed for LineUp Ocean consists of artificial reefs, visible in underwater images.

Their complex architecture, made possible by custom 3D concrete printing, is designed to multiply cavities and shelter zones.

Volumes are organized into galleries and alveoli sized according to local species, creating refuges for marine fauna and flora.

The natural roughness of printed surfaces is a real added value: it enhances the attachment of microorganisms, algae and, progressively, the entire marine community.

The first colonizations visible in the images clearly illustrate this habitat function.

An innovative material incorporating oyster shells

Beyond geometry, the material itself supports this environmental approach.

The 3D modules are produced using low-carbon concrete, in which part of the sand is replaced by recycled oyster shell waste.

This innovation reduces the extraction of natural aggregates and lowers the hydraulic binder content.

The formulation remains fully compatible with additive manufacturing and concrete extrusion, ensuring high mechanical performance within a circular economy framework.

Additive manufacturing serving marine biodiversity

By combining 3D concrete printing, custom design and more responsible materials, this partnership with LineUp Ocean demonstrates how additive technology can support the ecological transition of maritime infrastructure.

Ecological ballast blocks, complex artificial reefs and rough surfaces promoting colonization — every detail is designed to provide new living substrates for underwater ecosystems.

For 3D Concrete, these projects confirm the potential of 3D concrete printing as an innovation tool serving biodiversity and sustainable maritime development.

<img src="htts://3dconcrete.fr/actualités/https://3dconcrete.fr/modules-marins-en-impression-3d-beton/marinemodules.jpg" alt="Marine modules, low-carbon 3D concrete printing, marine biodiversity, 3D Concrete, Perpignan, Pyrénées-Orientales, Occitanie">